Packaging optimisation

We take a close look at the recyclability of packaging

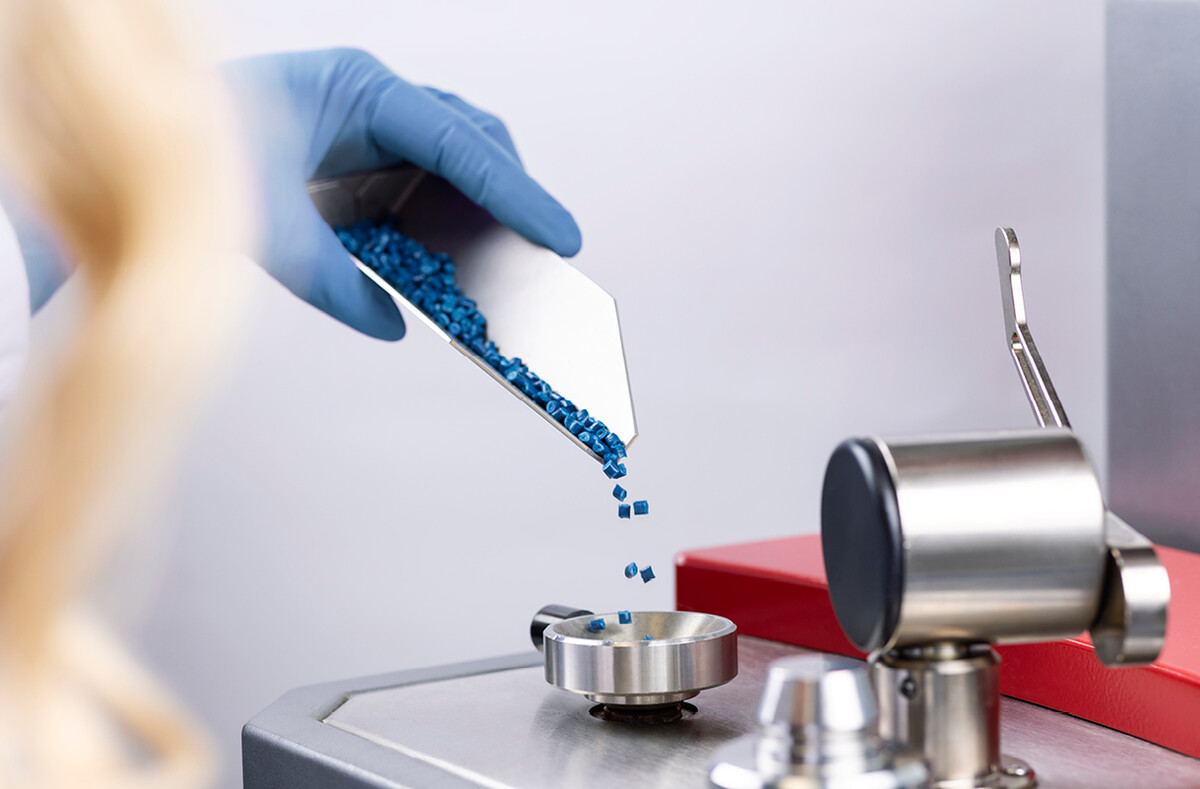

Recyclates - tomorrows’s raw materials. We advise you on your transition to recycled materials and get your company ready to meet market requirements. Benefit from our experts’ industry-leading know-how: the Centre of Competence for Plastics Recycling run by Interzero is Europe’s leading institution of its kind, and offers extensive guidance in the development and use of high-quality costum recompounds. At the end of 2021, the competence centre received accreditations for further testing methods, including UL94 for determining the burning speeds of plastics.

Greater use of recycled plastics is a key factor for ensuring the success of efforts to expand the reach of the circular economy. Recycled plastics reduce dependencies on petroleum-based raw materials while also cutting carbon emissions. Policymakers are therefore keen to ensure their greater use – not least with legislation that is aimed at significantly increasing demand for market-ready recyclates.

What does the new Act mean for manufacturers and retailers?

For brand owners and distributors, the goal must now be to embrace the transition to suitable recycled materials as soon as possible to maximise the benefits offered by this trend while maintaining their competitive edge.

Companies looking to procure and deploy recycled raw materials can rely on strong support from Interzero, ensuring these recyclates not only comply with EU legislation but are also attractive to the environmentally-conscious consumer. Customer benefits include being able to draw directly on the know-how offered by our Centre of Competence as well as full access to our extensive technical facilities for developing innovative and individual recyclates. Our Centre offers a range of ultramodern systems for assessing material quality: from mechanical, thermal and rheological properties through to analyses of flammability, sensory aspects and colour. Material processing machinery and an NIR separator are also provided to allow the simulation of packaging behaviour in real-world sorting plants. In March 2020, the Centre of Competence received its official accreditation to the international laboratory standard EN/ISO 17025, and is currently the only accredited research institution in the EU specialising in the development and analysis of recycled plastics.

The service catalogue provides a holistic overview of the equipment and methods the laboratory has to offer.

We support you in the integration of recycled plastics.

We develop customized, high-quality materials from post-consumer waste (PCR) and post-industrial waste (PIR) sources.

We analyse and test any plastic sample in accordance with international standards and internally developed methods.

We evaluate the quality of newly developed and existing plastic materials for you.

We are always up to date with the latest legal requirements (REACH and EU directives) and are right by your side as your consultants.

We help you save and optimize costs and energy in production processes.

Recycled materials modified to customer requirements can already be found in many industrial and household products. Our Centre of Competence continues to improve both the quality and the environmental footprint of these recycled plastics. A study by the Fraunhofer UMSICHT organisation has shown that using Procyclen instead of primary (oil-based) plastics, for example, saves 1,002 kg of greenhouse gases per tonne on average – cutting climate-damaging emissions by around 56 percent.

Managing Director Interzero Plastics Innovation