Life-cycle analysis shows: recycling is the clear winner

Protecting the climate means closing loops

For 15 years, this distinguished institute has been investigating how Interzero’s recycling activities impact resource consumption and the degree to which the management of materials in the loop can reduce emissions of harmful greenhouse gases. In the Sustainability and Resources Management department at Fraunhofer UMSICHT, geoscientists work together with chemical engineers, landscape ecologists and industrial engineers.

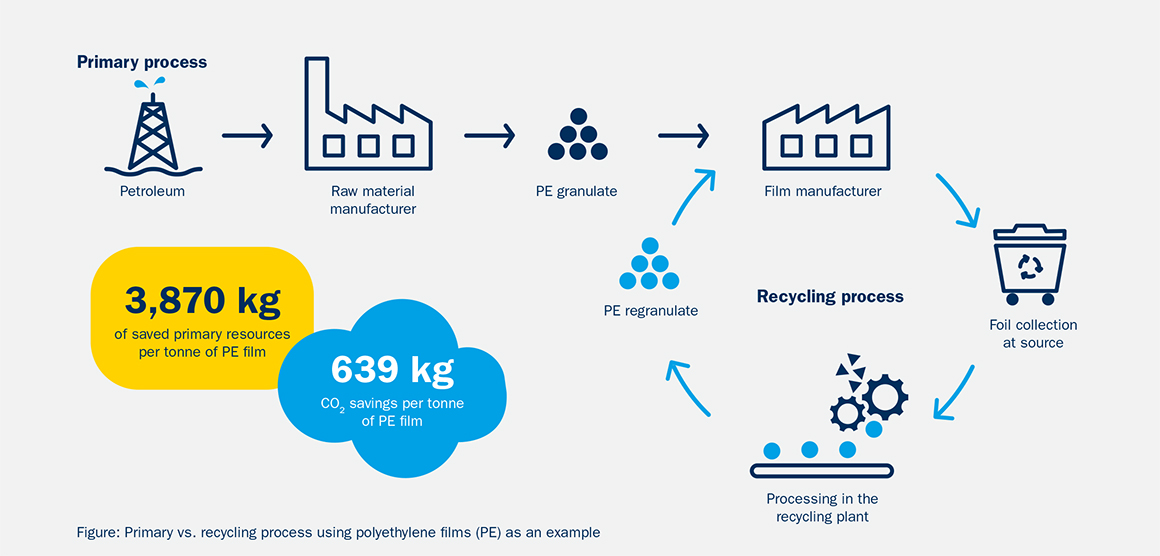

The "resources SAVED by recycling" study impresses with its special methodology: it allows the resource and greenhouse gas consumption of primary production to be compared with the consumption that occurs during processing within Interzero. First, the scientists determine the amount of resources and climate-damaging gases that are consumed or released in primary production. Then they examine the resources and greenhouse gases required for recycling. The difference between the two calculations yields the detailed environmental effect for each individual material flow.

Making recycling activities measurable

As a first step, researchers take a closer look at each individual material flow. Taking polyethylene (PE) as an example, all the process steps involved in making the plastic – from oil extraction and transportation to the refinery to distillation and polymerisation – are taken into account. The same approach is taken to the secondary process: starting from picking up used plastics to sorting and preparation, and then on to shredding and melting in the extruder to make the PE regranulate.

Fraunhofer UMSICHT uses Interzero key figures on recycling for data collection and supplements them with key figures from databases. The life cycle assessment programme "GaBi" calculates the raw material input and greenhouse gas emissions in the primary process and in the recycling process respectively. One ton of polyethylen produced in primary production consumes around 5,226 kg of raw materials and 1,674 kg of greenhouse gases - this compares to savings of 3,870 kg of primary resources and 639 kg of greenhouse gases per tonne of recycled polyethylene.

Frequently asked questions regarding the study:

- What is the goal of Interzero’s “resources SAVED by recycling” study?

Interzero stands for a world without waste, where resources are consistently kept in circulation, and waste is minimised as much as possible. A future-proof circular economy that actively contributes to climate and resource protection. But what does this mean in practical terms? To what extent can greenhouse gas emissions be avoided, or natural resources conserved?

Accurate data is a key factor in demonstrating the ecological benefits of the circular economy. To inform the public, provide arguments for the circular transformation of the economy, and support our customers in transparent sustainability communication, we have been having the environmental impacts of recycling independently assessed by scientists for over 15 years. The annual life cycle assessment (LCA) conducted by the Fraunhofer UMSICHT institute proves the sustainable impact of our work.

- What data do the scientists use?

The comprehensive life cycle assessment is based on a detailed comparison of primary production versus recycling, covering all necessary process steps. The data used includes:

- Interzero's data on different material types, sorting and recovery quantities, average transport and collection distances, vehicle types, as well as the electricity and heat requirements of sorting and processing facilities.

- Data for greenhouse gas emissions and raw material usage: These are sourced from Sphera’s LCA for Experts database and cover the emissions and resource use associated with the primary production of new materials, such as plastics (including activities like oil extraction, transportation, and processing steps).

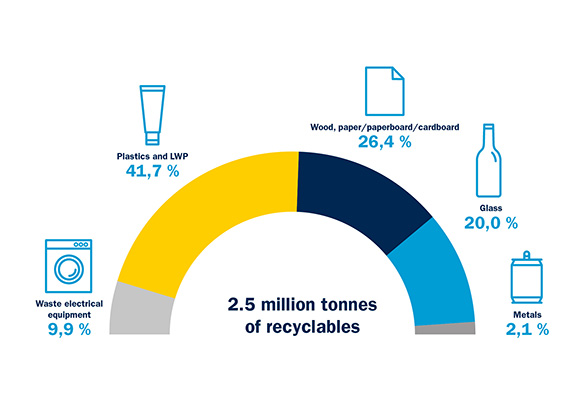

- Which material streams are the focus of the study?

The study currently focuses on five material streams: metals, waste electrical and electronic equipment (WEEE), plastics and lightweight packaging (LWP), wood, paper, paperboard, cardboard, and glass. In 2023, Interzero processed a total of 2.5 million tonnes of recyclable materials, leading to savings of 11.2 million tonnes of primary resources and 1.2 million tonnes of greenhouse gas emissions.

- How does the study work?

The process begins with Fraunhofer UMSICHT developing a questionnaire to capture details about the recycling processes and identify which primary products are being replaced, such as new paper or plastics. Interzero collects this data, which is then verified by Fraunhofer UMSICHT. Next, the scientists create life cycle assessment (LCA) models using the "LCA for Experts" software and compare the recycling data with data from primary production. After analysis and interpretation, the results can be communicated, highlighting the corresponding savings.

- Why is it so important to measure resource consumption?

Humanity is living far beyond its means – a reality that the Earth Overshoot Day highlights each year. According to calculations by the Global Footprint Network, by 2024, all the natural resources that our planet can renew in a year were already depleted by August 1st. This underscores the importance of raising awareness about the benefits of recycling.

The production of virgin plastics, for instance, involves significant resource consumption – from oil extraction and transportation to refineries, to polymerisation. However, when plastics are recycled, there is no need for further extraction from nature, energy use decreases, and fewer climate-damaging greenhouse gases are emitted.

Through Interzero's circular solutions alone, the global Earth Overshoot date was pushed back by more than seven minutes in 2024.

- How can resource conservation through recycling be measured?

There are several methods for measuring resource consumption, many of which assess the availability and accessibility of resources. While these methods yield valuable insights, the results can be difficult to convey. Therefore, we have opted for a simpler approach, focusing on the masses of materials that are extracted or, in some cases, incinerated.

Specifically, resource consumption includes the use of non-renewable energy resources (such as lignite, coal, natural gas, and crude oil) as well as renewable resources (such as wind and solar power). Additionally, it covers the mass of material resources, including ores, minerals, and overburden. These resource amounts are attributed to both the recycling process and the primary production process, with the difference representing the resource savings, expressed in tonnes.

- What role does recycling play in climate protection?

The climate crisis poses a significant threat to both people and the environment, already leading to considerable economic and social costs. In Germany, according to the Federal Environment Agency, around 40 per cent of greenhouse gas emissions are linked to the extraction and initial processing of raw materials. Recycling and maintaining materials in circulation is, therefore, an essential strategy for reducing emissions and preserving a livable environment.

Senior Marketing Manager