Big-Bagging building waste for reuse

Xella and Interzero close the resource loop for Ytong and Multipor scrap.

Together with Duisburg-based manufacturer Xella Deutschland GmbH, Interzero has developed a simple and effective model to close the resource loop for Ytong cellular concrete and Multipor mineral wool board. Much too valuable to throw away: for many years, Ytong cellular concrete and Multipor mineral wool board have been popular with builders as wall construction and insulation materials – especially as thermal insulators. On most sites, scrap created during building work – although only in small amounts – nonetheless ends up in the construction debris container as waste. This not only means disposal costs for the builder but also the loss of the scrap as a raw material.

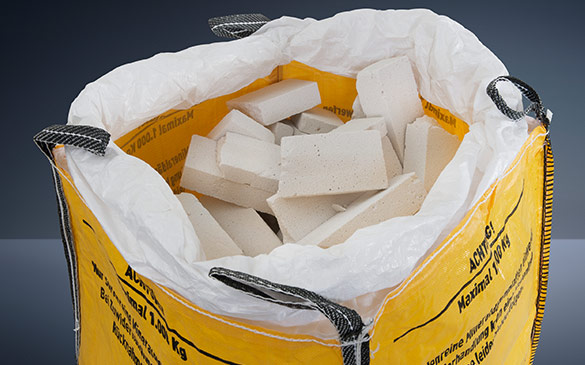

The solution: sort and collect scrap into Big-Bags

Looking for an ecologically and economically beneficial solution for its customers, building material manufacturer Xella contacted Interzero. The joint solution developed was as simple as it was effective: apart from the material itself, Xella’s customers can order a “site set” consisting of Big-Bags, coded tie-off straps (“talons”), a take-back form and an accompanying information pack. Each Big-Bag can hold a maximum of one tonne of material (here: Ytong and Multipor), which customers sort and collect directly at the site. Once tied-off with the coded talons and stacked on a pallet, Interzero then picks up the Big-Bags and transports the sorted scrap back to one of Xella’s factories. Here, the scrap remnants are ground up and used again in production.

Projektleiterin Business Development