The Right Chemistry: VIP Tour of the Interzero Plastics Innovations Centre of Competence.

Outside: The kind of building you’d find on any industrial estate. Inside: A high-tech lab that’s second-to-none. Nine specialists are hard at work here on the future of plastics recycling. With furrowed brows, they monitor analysis equipment and pilot facilities, take samples, shake test tubes and check the readings on the monitors. Interzero Plastics Innovation – the name says it all: As soon as you enter this recycling centre of competence in Lenart, Slovenia, you sense a unique atmosphere of scientific curiosity, precision and a passion for sustainable innovation.

“We’re very proud to have established the EU’s first – and to date only – research facility accredited to EN/ISO 1702 that specialises in the analysis and development of recycled materials,” says Dr Manica Ulcnik-Krump, an industrial chemist by trade and Managing Director of Interzero Plastics Innovations. Her team’s extensive plastics know-how, the modern lab equipment for investigating chemical, thermal, physical and mechanical processes, plus a small in-house recycling plant, all create the environment needed for developing new and competitive solutions for the circular economy. “We definitely have the right chemistry,” Ulcnik-Krump says with a wink: “and not just in the lab but also in the projects we work on with customers and partners.”

Recyclability? Check!

The team is kept very busy by the various steps needed to complete customer orders on time. Analysing recyclability is one of the specific assignments this work involves. Every year, the team handles around 250 items of packaging from manufacturers across Europe. One example is ‘Pouch 5’ from Gualapack, which was put through its paces here to confirm that it really is the first 100% recyclable monomaterial retort pouch. The lab’s seal of approval for the pouch was a key criterion for major brands like Nestlé and Kraft Heinz, who now use the pouch for their products. With the ‘Made for Recycling’ quality mark, these brands can show that their packaging is designed to be resource-friendly – and conforms to the requirements of the EU Packaging and Packaging Waste Regulation (PPWR). The lab in Lenart is also the right port of call for recyclability assessments to the RecyClass standard: these are relevant for the packaging materials PP and HDPE, and automotive modules, for example.

A second string to their bow: developing new materials

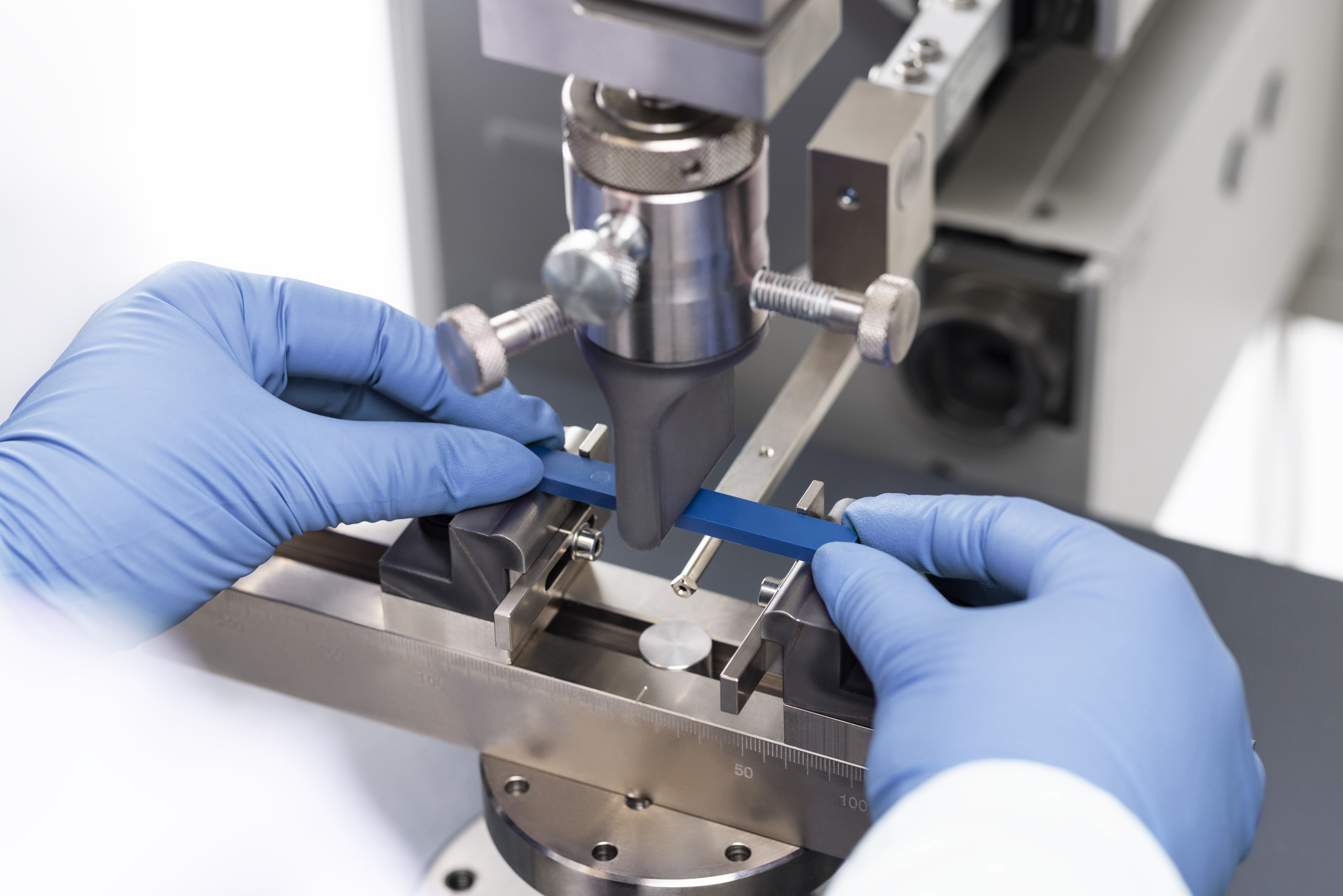

How does packaging actually behave in a real sorting plant? This can be accurately evaluated with the lab’s very own NIR separator. Ultra-modern technical equipment is also available for material assessment and processing. From mechanical, thermal and rheological properties to sensory aspects and colour, plastics are not just merely analysed in Lenart but are also remodelled to suit a very wide range of applications. “First of all, we need 3 kg of the raw material the customer will be using for their product and 3 kg of their manufactured plastic part,” Ulcnik-Krump explains. Various tests are used to provide feedback on how the polymer changes during the customer’s processing workflow. The team can then adjust the recycled plastic to be a perfect match for the required properties.

Every year, this approach produces around 40 custom recycled material recipes as tailor-made solutions for the plastics processing industry. One award-winning example is the ‘Memo Box’, a reusable shipping box from Memo AG made with recycled plastic, which won the 2025 German Sustainability Prize in the ‘Products’ category. The box is exceptionally stable, tough and colourful – all thanks to the bespoke Procyclen recycled materials from the Interzero Centre of Competence.

Enablers for the real circular economy

Working together with customers and partners, the experts in Lenart are always dreaming up exciting new innovations. Such as the first mechanical recycling process that enables blow mould products like bottles to be made entirely from recycled packaging waste supplied by the German ‘yellow bag’ collections. Patented in 2023, this method produces high-density polyethylene (HDPE) with a fluidity that is comparable with virgin plastic. “This lets us achieve significant reductions in raw materials, energy, carbon emissions and effort,” explains Ulcnik-Krump.

So it’s not surprising that the expertise on offer at Interzero’s Centre of Competence is in demand around the world. From quality assessments of feedstocks for chemical recycling on the one hand to implementing PPWR requirements for the restriction of harmful chemicals on the other. With the right analysis in place, the Centre’s specialists help their customers to comply with the legal limits for packaging while providing them with support for the necessary documentation and audits. Making the real circular economy happen – it’s also about finding the right chemistry.

![[Translate to English - Englisch:] [Translate to English - Englisch:]](/fileadmin/_processed_/1/4/csm_230606-AGA-Tridi-Indonesia-PET-recycling_e3dcd2ad90.jpg)