Plastics in the loop: think bigger!

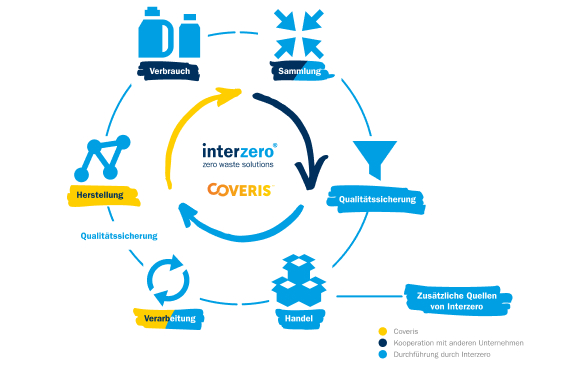

A milestone on the way to zero waste: Interzero and packaging manufacturer Coveris signed a strategic partnership aimed at closing the loop for plastics. Plastic film is now being recycled on a large scale – and being made into new sustainable packaging.

The clock is ticking. From 2030, all plastic packaging must contain the minimum proportion of recycled content defined in the EU Packaging and Packaging Waste Regulation (PPWR). Good news for climate action and resource conservation, but a challenge for manufacturers: how can they ensure continuous access to an adequate volume of recycled raw materials at a uniform level of quality?

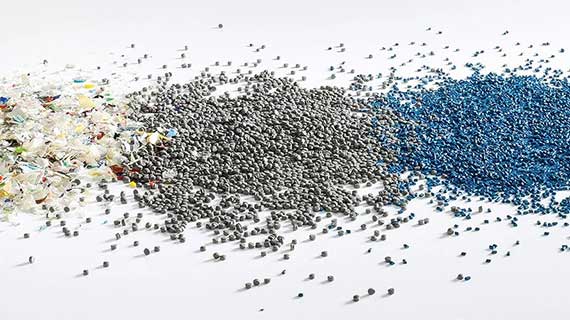

Together, Coveris and Interzero are showing how this can be done. With its ReCover product range, Coveris had already made significant progress towards a closed-loop system. The partnership with Interzero, as an international supplier of raw materials, now lets it scale up these technical innovations. The materials collected and sorted by Interzero are recycled mechanically in the ReCover plants, and processed into high-quality recycled materials. These materials are then used as input for packaging production to create a sustainable, closed-loop economy.

“Creating real closed-loop solutions together”

Interview: Philipp Niehues, ReCover Business Development Director at Coveris

How does the partnership with Interzero support the Coveris ‘no waste’ vision?

As a provider of industrial and food-grade packaging solutions, we are already focusing our efforts on integrating sustainable materials with a high proportion of recycled plastics (PCR) into our products. Indeed, many of our industrial customers are already using packaging with up to 80% PCR. Thanks to the partnership with Interzero, we’re now aiming to close this loop even further and offer real closed-loop solutions. Our customers will be given the option of returning their transport packaging waste to us, so that we can ensure this waste is used in new customer products. Together, we can work to create a more sustainable value chain, reduce waste and apply our ‘no waste’ philosophy to real-world problems.

What does each partner bring to the table?

Being able to offer these kind of solutions is nothing if not a logistical challenge – and this is where Interzero comes in. Coveris has already established capacities for plastic film recycling in the UK and is now working to expand this infrastructure within the EU. We are seeing strong demand for high-quality recycled materials for plastic film. Thanks to its long-standing partnership with Interzero, Coveris has secured access to large quantities of high-quality plastic film waste as a raw material, which ensures a constant and sustainable supply of recycled materials.

What starting materials are suitable for the closed-loop production process at Coveris?

At the moment, we’re concentrating on high-quality PCR materials from back-of-the-store waste streams. These offer us the best starting-point for producing high-quality recycled plastic films. In the medium term, however, plastic film waste from LWP plants will become more important. To ensure we can return these materials efficiently to the loop, we are investing in specific kinds of new technologies that will enable high-quality processing into premium pellets. We also want to work with Interzero to ensure a continuous process of knowledge transfer and develop additional waste streams. This lets us expand the availability of sustainable raw materials for the packaging industry and develop innovative recycling solutions.

Where are the recycled materials from your ReCover plants now being used – and what level of raw material demand do you expect to see over the next few years?

Key applications at the moment include shrink tubing and covers for securely protecting pallet loads. Powerstretch films are also important as these have a characteristically high puncture resistance and stability while also requiring less material to produce. We also offer a fully recyclable solution for multi-pack products with Duralite™ R, our multiple award-winning range of shrink films. Coveris currently processes around 120,000 t of LDPE pellets every year, with a growing proportion of recycled material. Over the next three years, we expect to see the annual demand for recycled LDPE rising to about 50,000 t. The large proportion of recycled materials in these packaging solutions is driving a sustainable and resource-friendly packaging strategy that does not compromise on quality or performance.

Director Key Accounts, Interzero