Fakuma 2017: Interseroh to attend the world leading event

International trade fair for industrial plastics processing

Cologne. This year, INTERSEROH Dienstleistungs GmbH will once more be attending the Fakuma trade fair in Friedrichshafen. At the international trade fair for industrial plastics processing, which is taking place from 17th-21st October 2017, the subsidiary company of recycling specialist ALBA Group will be presenting its Recycled-Resource business division and its accompanying range of products and services. In Hall B1-1125, the provider of environmental services will demonstrate the wide-ranging possibilities offered through the use of recycled plastics gained from post-consumer material.

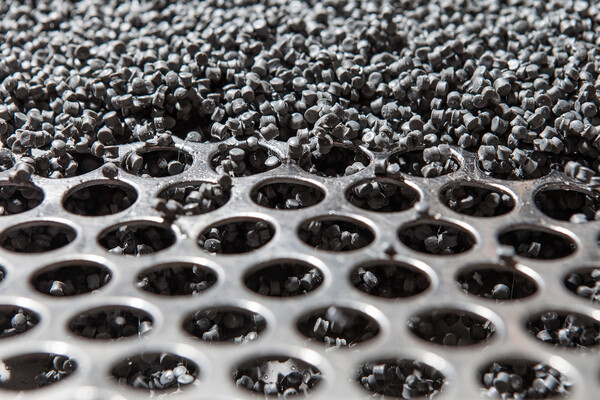

The Recycled-Resource production process – which Interseroh developed itself and has won several awards – is based on a sophisticated upcycling recompounding process. The comprehensive, high-tech sorting of the plastic waste is followed by the re-compounding, encompassing the extrusion, re-stabilising and reconstruction of the molecular structure, as well as the chemical modification with the addition of additives so as to achieve the precise plastic characteristics that are required by the customer. According to a study by the Fraunhofer Institute UMSICHT, the use of the resulting recycled plastics Procyclen and Recythen provides a valuable contribution to the sustainable use of resources in comparison with new granulate, and reduces the emissions of greenhouse gases during the manufacturing by 30 to 50 per cent.

“Thanks to the latest developments, we are now able to integrate special inorganic components in the production process of Procyclen as a bulking agent,” highlights Dr. Manica Ulcnik-Krump, Head of Business Unit Recycled-Resource at Interseroh. “This is a unique development in the market for the processing of post-consumer material.” An example in this respect is glass fibre reinforcement, which is achieved through the successful binding of glass fibres and plastic matrix.

The key developments behind these advances have taken place in the company’s in-house competence centre for plastics recycling, which Interseroh has been operating in Maribor, Slovenia, since September 2016. It is here that Interseroh has developed preparations which ensure material attributes such as durability, transport safety, mechanical stability up to -30°C and UV-resistance. On this basis, the recycling services provider is able to manufacture recycled plastics in accordance with individual requirements and purposes. In addition to polypropylene for example, materials such as high-density polyethylene, polystyrene and other technical plastics can also be processed.

Fakuma is the world leading event for industrial plastics processing and is celebrating its 25-year anniversary this year. At the five-day trade fair in Friedrichshafen, over 1,700 visiting exhibitors from 35 different countries will present their products and services on 85,000 square metres of exhibition space, providing an holistic overview of all plastics technologies. Over 40,000 people are expected to visit the event from 120 different countries.

Free use of the attached picture is authorised, provided the source "ALBA Group" is acknowledged.

- Press releases

- Interzero

- Interseroh+

About Interzero:

Interzero is one of the leading service providers in the field of closing product, material and logistics loops as well as innovation leader in plastics recycling with the largest sorting capacity in Europe. Under the guiding principle of “zero waste solutions”, the company supports over 50,000 customers throughout Europe in the responsible handling of recyclable materials, thus helping them to improve their own sustainability performance and conserve primary resources.

With about 2,000 employees, the company achieves a turnover of over one billion euros (2021). According to Fraunhofer UMSICHT, Interzero’s recycling activities could save one million tonnes of greenhouse gases compared to primary production and more than 8.7 million tonnes of primary raw materials in 2022 alone. As a pioneer in the circular economy, Interzero is winner of the German Sustainability Award as well as the related special award in the “Resources” transformation field for 2024.

Further information can be found at www.interzero.com.